Stainless Steel Crimped Wire Mesh 0.5-10mm Width Customized For Mining

Product Details:

| Place of Origin: | China |

| Brand Name: | FUHANG |

| Certification: | ISO9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Square Meter |

|---|---|

| Price: | 1-30 Square Meter $2/Square Meter >30 Square Meters $1/Square Meter |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5000 square meter /15 Days |

|

Detail Information |

|||

| Features: | Alkali-resisting Etc.,Acid Resistant,Acid-resisting | Product Name: | Crimped Wire Mesh For Mining |

|---|---|---|---|

| Application: | Decorative Wire Mesh | Technique: | Woven |

| Type: | Crimped Wire Mesh | Material: | Stainless Steel Wire 45# Medium Carbon Steel 65# Mn Steel |

| Wire Diameter: | 0.5-10mm | Hole Shape: | Square Hole,as Per Requirement |

| Color: | Stainless Steel Wire 45# Medium Carbon Steel 65# Mn Steel | Length: | Customized |

| Surface Treatment: | Untreatment,copper | Width: | Customized |

| Feature: | Beautiful | Certification: | ISO |

| Keyword: | Crimped Wire Mesh | ||

| High Light: | Stainless Steel Crimped Wire Mesh,10mm Crimped Wire Mesh,Customized Wire Mesh SS |

||

Product Description

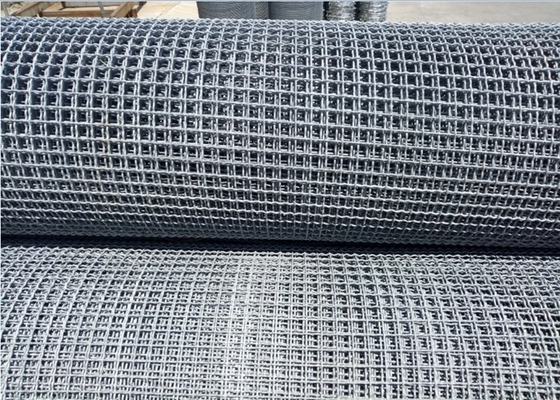

Crimped Wire Mesh for Mining

Fuhang Company is a leading manufacturer and supplier of crimped mining screens mesh in China. We provide professional crimped mining mesh, including double crimped and lock crimped wire mesh. The crimped wire mesh is usually used as a mining screen, widely used in the washing, sizing and screening of aggregates, sand and gravel in the mining, coal, and aggregate production industries. Our mining screens are made of high-quality carbon steel or stainless steel, with good screening accuracy, high strength and high wear resistance.

![]()

Mining screen mesh has higher strength. Its wear resistance can be improved if a certain amount of manganese is added to it, which makes it more suitable for use in high-strength working environments such as ore screening. 65MN steel is one of the most commonly used mining screen materials in mining, quarrying and agglomeration industries. Although the hardness of the stainless steel mining screen is not as good as high carbon steel, its corrosion resistance are better than high carbon steel, and its service life is longer.

We generally choose high-quality stainless steel wire, low-carbon steel wire, 45# medium-carbon steel wire, and 65# manganese steel wire as the material for mining crimped wire mesh. Wires of these types of materials have their own advantages and characteristics.

1. Stainless steel wire: resistant to acid and alkali and corrosion. But the hardness and wear resistance are not as good as 45# medium carbon steel and 65# Mn steel; stainless steel crimped mesh is suitable for screening materials with acid and alkali.

2. Low-carbon steel: It has the most advantage in price, but the hardness and wear resistance are the worst among these materials. However, the low-carbon steel crimped mesh can be welded with other low-carbon steel materials for easy installation. If the customer needs to weld the crimped wire mesh to the frame or machine, you can choose this material of the crimped wire mesh. Low-carbon steel crimped wire mesh is suitable for screening general materials.

3. 45# Medium Carbon Steel: The hardness and wear resistance of the wire rod of this material are very good, and the price is also relatively advantageous. It is an ideal choice for many mine screens. Crimped wire mesh made of 45# steel wire cannot be used for welding. Generally, the iron plate is made into a U-shape, clamped to the edge of the crimped mesh, and then the iron plate is welded tightly. 45# medium carbon steel crimped wire mesh is suitable for screening most materials without acid and alkali.

4. 65# Mn steel has the same characteristics as 45# medium carbon steel, and it is not suitable for welding. But the hardness and wear resistance of 65# Mn steel are better than 45# medium carbon steel. It is especially suitable for mines to screen hard materials such as stones. Of course, the price is relatively more expensive.

![]()

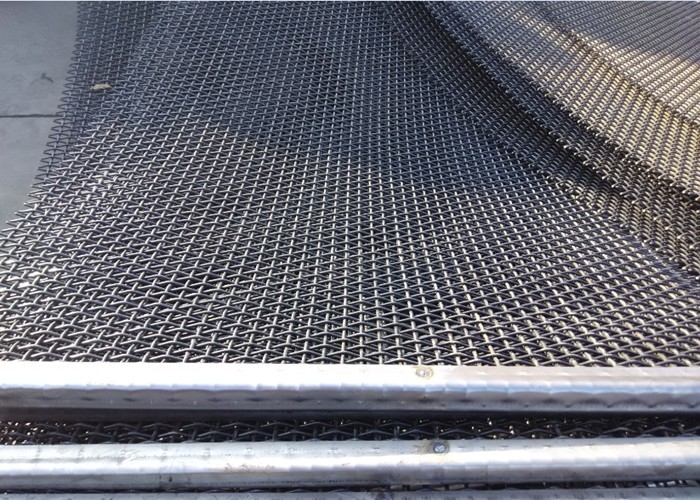

Crimped Wire Mesh for Mining Features

High strength

Wear and corrosion resistance

Uniform mesh and high screening rate

Long-lasting