Wear Resistance Stainless Steel Sintered Wire Mesh Filters ISO9001 Approved

Product Details:

| Place of Origin: | China |

| Brand Name: | FUHANG |

| Certification: | ISO9001 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Square Meter |

|---|---|

| Price: | 1-30 Square Meter $2/Square Meter >30 Square Meters $1/Square Meter |

| Packaging Details: | paper tube inside+ wodden box +plastic bag |

| Delivery Time: | 5-8 work days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000 square meter /15 Days |

|

Detail Information |

|||

| Name: | Stainless Steel Sintered Wire Mesh | Application: | Gas Distribution |

|---|---|---|---|

| Feature: | Good Corrosion Resistance, Good Heat Resistance | Material: | SUS316L SUS304 |

| High Light: | Stainless Steel Sintered Wire Mesh,ISO9001 Stainless Steel Filter Mesh |

||

Product Description

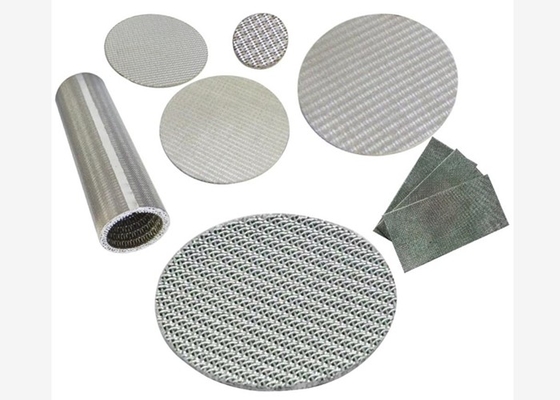

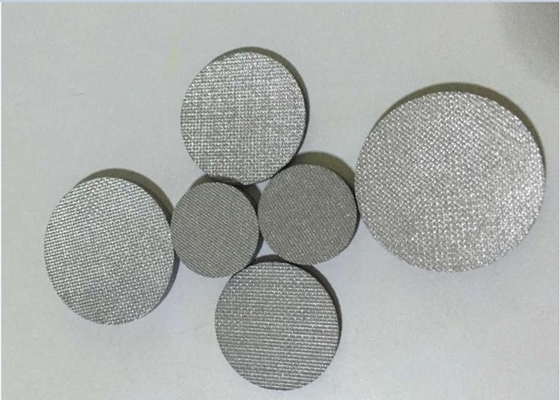

Stainless Steel Sintered Mesh Stainless Steel Wire Mesh Filters

Stainless steel sintered mesh is a new type of filter material with high mechanical strength and overall rigidity, which is made of multi-layer metal wire woven mesh through special lamination and vacuum sintering processes. The meshes of each layer of wire mesh are interlaced to form a uniform and ideal filter structure. It not only overcomes the low strength, poor rigidity, and unstable mesh shape of ordinary metal wire mesh, but also can control the pore size of the material. Permeability and strength characteristics are reasonably matched and designed, so that it has excellent filtration accuracy, filtration resistance, mechanical strength, wear resistance, heat resistance and workability. The overall performance is significantly better than that of sintered metal powder, ceramics, Fiber, filter cloth, filter paper and other types of filter materials.

![]()

![]()

Five-layer sintered mesh is the most widely used standard structure of sintered mesh, generally a five-layer structure, divided into five parts: protective layer, filter control layer, dispersion layer, supporting framework layer, and framework layer.

This kind of filter material not only has uniform and stable filtration accuracy, but also has extremely high mechanical strength and compressive strength; it is an ideal filter material for occasions with high compressive strength and uniform filter particle size; because its filtration mechanism is the surface layer Filtering, and the mesh channels are smooth, so it has excellent backwashing regeneration performance, can be used repeatedly for a long time, and is especially suitable for continuous and automated operation processes. It is incomparable to any filter material. The sintered mesh material is easy to be formed, processed and welded, and can be processed into various forms of filter elements such as round, cylindrical, cone, and corrugated shapes.

![]()

![]()

Sintered mesh thickness

Thickness: It is determined by the number of layers of the sintered mesh. The thickness of the five-layer standard sintered mesh is generally 1.7mm

Sintered mesh size

Size: Determined according to the size of the sintering furnace cavity, common specifications are 500mmX1000mm, 1000mmX1200mm

Sintered mesh material

Material: The most common is SUS316L SUS304, and there are also copper sintered mesh, high-strength nickel-chromium mesh, etc. upon request.

![]()

Characteristic

1. Has extremely high mechanical strength and compressive strength. Good processing, welding and assembly performance, easy to use.

2. The filter layer is in the second layer, so that it has been well protected and divided, and the filtration accuracy can reach uniform filtration performance, ensuring its high stability.

3. Use 316L material, good corrosion resistance, good heat resistance, and can be used for filtering in temperature of -200℃~480℃ and acid-base environment.

4. The surface filter structure with excellent countercurrent cleaning effect, so the countercurrent cleaning effect is good, it can be used repeatedly and has a long life. (It can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).

![]()

Application

1. Used as a dispersive cooling material in high temperature environment

2. Used for gas distribution, liquidized bed orifice material

3. Used for high-precision, high-reliability and high-temperature filter materials

4. Used for high pressure backwash oil filter